Product Features

For Manufacturing

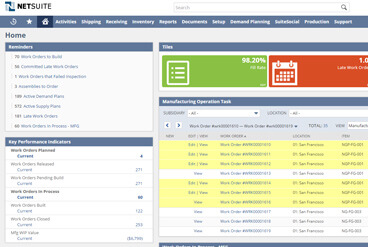

Home / Production Control

Menu

Production Control

Create, release, update and monitor work orders throughout the production process

NetSuite offers the flexibility your business needs to manage your production process exactly the way you want. Each location can choose to manufacture the same product the way that best fits their facilities capabilities and data requirements. With NetSuite the ability to backflush, track WIP and capture labor can be configured to ensure you get the right information and control of your manufacturing processes.

Key Benefits

- Location specific configuration of production control.

- Automatic status updates with workflow.

- Real-time view of in-process work orders.

- Batch updates for completing and closing orders.