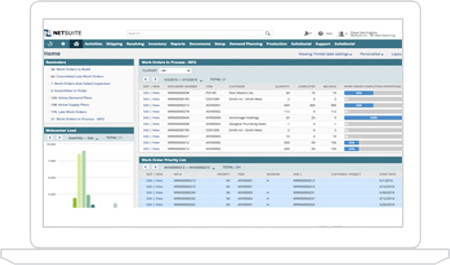

Work Order Management

Easily create, release, close and complete work orders with automatic scheduling for efficient and scalable production control

NetSuite’s manufacturing functionality can be configured depending on how much control and influence you want over your production process. In addition to using the work order as the control document, NetSuite also offers the ability to work in an environment without work orders for manufacturers are following lean principals. NetSuite’s advanced manufacturing module offers the ability to manufacture in batches with automatic batch creation, full traceability, production control and scheduling.

Features

Discrete Manufacturing

NetSuite offers discrete manufacturers many options for how they manage their production processes regardless of their size, complexity or business maturity. Whether you want to work in an environment without work orders, backflush all of the materials upon completion, issue and track materials and labor as work in process cost or define and track labor through a routing, NetSuite has the features to get you the information you need.

Key Capabilities:

- Work Orders & Assemblies

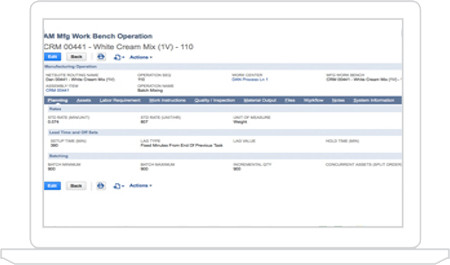

- WIP & Routings

- Advanced Manufacturing

Batch Processing

NetSuite Advanced Manufacturing offers companies the flexibility to define batch sizes during the production process and automatically creates batch records. Every batch is processed and tracked uniquely and when combined with NetSuite’s native lot tracking functionality provides complete end-to-end traceability. Machines, employees, work centers and assets are then scheduled and assigned to each individual batch and the manufacturing execution systems barcode and tablet interfaces ensure that all this information is tracked and updated in real time.

- Automated Batch Management

- Full Traceability

- Quality Control

Shop Floor Control

Obtaining accurate information from the shop floor is vital to all aspects of running a manufacturing business and without it you run the risk making critical business decisions without all of the necessary information. Barcode scanners have typically been used to gather production information, but they are limited in the amount of information they can feed back to the user / operator. So NetSuite offers an intelligent tablet interface that provides instant feedback and visual warnings to the user when there are things they need to attend to.

- Tablet Interface

- Real-time updates

- Shop Floor to Top Floor Reporting